While cranking problems can be frustrating, identifying and correcting the root cause does not have to be.

The first step is to identify the symptoms. In a cranking system, you can divide your symptoms into one of three possible troubleshooting categories:

STEP 1 - Begin at the batteries

STEP 1 - Begin at the batteries

Charge the batteries and perform battery load test on the battery bank. If the load test fails, then individually test each battery and replace any faulty ones.

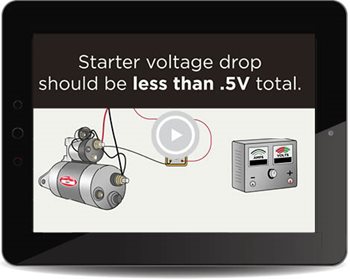

STEP 2 - Perform a voltage drop test

If the batteries charge sufficiently, then perform a voltage drop test on the starter main cables. The starter voltage drop should be less than .5V drop total on cranking circuit. This is an important step and is often the cause of a slow cranking complaint. Yet, voltage drop also is a leading cause of click or no-click complaints because almost every vehicle manufacturer uses the heavy positive post, located on the starter solenoid, as a place to pick up the current used to supply the control circuit.

STEP 3 - Identify the specific issue

Until now, the diagnostic path has remained the same regardless of the complaint. Now is where you address the specific issue.

- Slow Cranking: For the starter to be cranking, the control circuit would have to be working. So, if battery and cable checks are within specification and the vehicle still cranks slowly, then it’s a slow cranking problem and it’s time to replace the starter.

- Click No-Crank: Check the control circuit. If the starter does not contain an Integrated Magnetic Switch, or IMS, then a voltage drop test will need to be performed on the vehicle control circuit. If the starter does have an IMS switch function, then the technician will have to verify that the vehicle’s control circuit is providing voltage to the starter IMS.

- No-Click No-Crank: When this occurs, power is not being sent to the solenoid, making it very unlikely that the issue is related to the starter motor.

If all systems have been checked, and the starter is found to be the cause, the ring gear also should be inspected for damage that could cause future starter damage.

This tech tip has been one of our most popular, with the prior versions of the video racking up more than 700,000 views! Add it to your library—it’s a great reference and training tool for teams.